Sap is boiling! We tapped about thirteen trees so far, and collected about 20 gallons of sap today.

Tag: maple

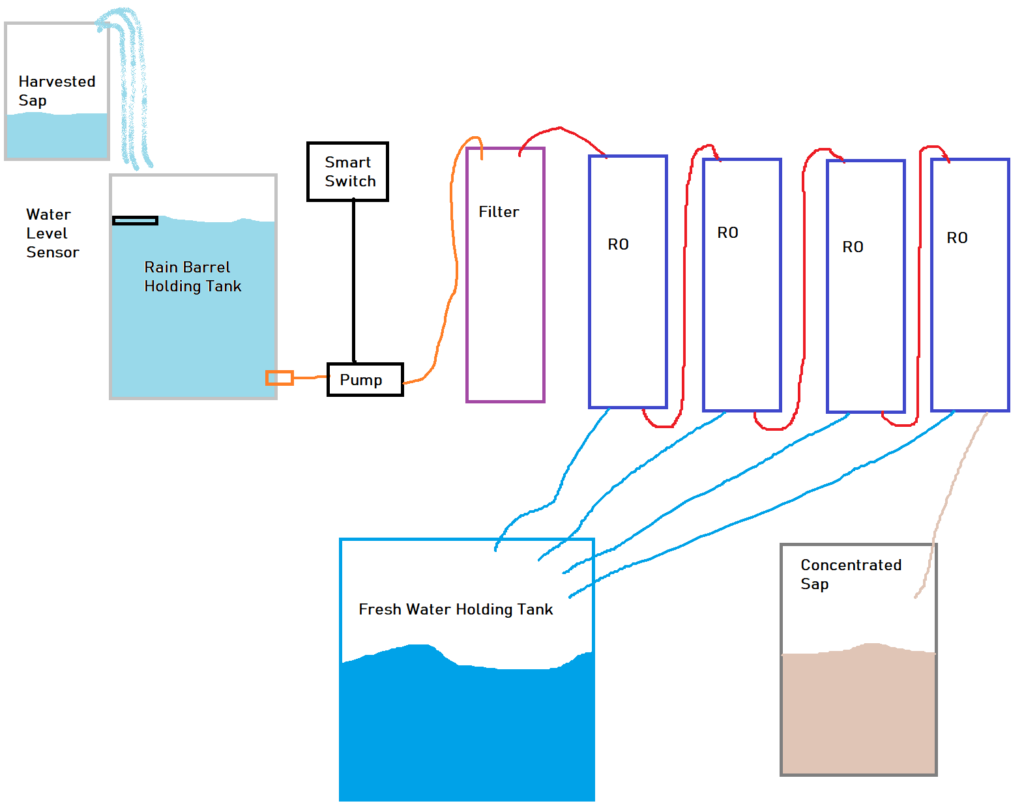

DIY Reverse Osmosis Filter for Maple Sap

Notes from the reverse osmosis system build we are planning:

Ideally, we run RO inside — lose 3% efficiency on RO for every degree drop, and systems are rated at 77 F. Is this bad for sap storage, though?

Multiple RO membranes connected in series (“dirty” out goes to next one’s “in”, “clean” out goes to fresh water collection). 3x or 4x membrane — more concentrated as fluid runs through each of the membranes. Diminishing returns, 3-4 max units.

Process:

Sap goes into rain barrel — need valve out from rain barrel. Sensor in sap holding tank and smart outlet for pump — turn off pump when tank is near empty.

Pumped from rain barrel holding tank to filter. Output from filter to input on first RO.

“Fresh water” output from each RO goes to fresh water holding tank (rain barrel). “Dirty stuff” output from each RO goes to input on next RO for farther concentration.

“Dirty stuff” output from final RO, the concentrated sap, goes into Digiboil (65L, ~17 gallons of liquid)

Little pump we use for brewing draws from Digiboil to fill boil trays on the burners.

RO system:

Pump — need to compare this one and this $40 one.

Water filter housing Either with 1/4″ inputs or 3/8″ inputs — prefer 3/8″

Water filter 10″ long x 2.5″ across filters — these look like they’d fit

RO membrane & housing combo but we can get replacement things from Ali for about $10

Connections:

Something from rain barrel to 3/8″ input on pump — GHT female and 3/8″ male

Something from 3/8″ output on pump to 3/8″ input on filter

Something from 3/8″ output on filter to 1/4″ input on RO

3/8″ tubing from rain barrel to pump, from pump to filter, and from filter to RO

1/4″ tubing to run between RO filters

1/4″ tubing from each RO to fresh water holding tank

1/4″ tubing from last RO to Digiboil

Maple Peanut Butter Eggs

Maple Peanut Butter Eggs

Course: DessertDifficulty: EasyIngredients

- Peanut Butter Filling

1 cup chunky peanut butter (unsweetened)

1/4 cup maple syrup

1 tbsp vanilla extract

1/4 cup all-purpose flour

- Maple Chocolate

4 oz 100% cocoa bakers chocolate

2 tbsp coconut oil

1/3 cup maple syrup

1 tbsp maple sugar

Method

- Line a plate with clingfilm or wax paper

- Combine the peanut butter filling ingredients and mix to combine

- In a double boiler, melt coconut oil

- Add chocolate to coconut oil and melt

- Stir in maple syrup and maple sugar

- Take about a tablespoon of peanut butter mixture and roll into an egg shape

- Roll peanut butter egg in chocolate to coat

- Carefully remove coated egg from chocolate and place on lined plate

- Once all eggs are coated, refrigerate for a few hours to solidify

Notes

- Because coconut oil is used in this chocolate, it has a very low melting point — it’ll make a mess if you hold it in your hand as you eat it. Replacing the coconut oil with butter would raise the melting point.

Maple Sap Season Coming To A Close

We’re getting to the end of maple sap season – collecting a last batch of sap and boiling this week. We should get another gallon or so of syrup, but the red maples are well into leafing out. I’ve heard a lot of descriptions of the sap flavour after bud-break … to me, it is tannin heavy. That would put us around four gallons of syrup for the year — and re-enforce my belief that the algorithm determined tapping date is when we should tap – even if that’s the second week of January!

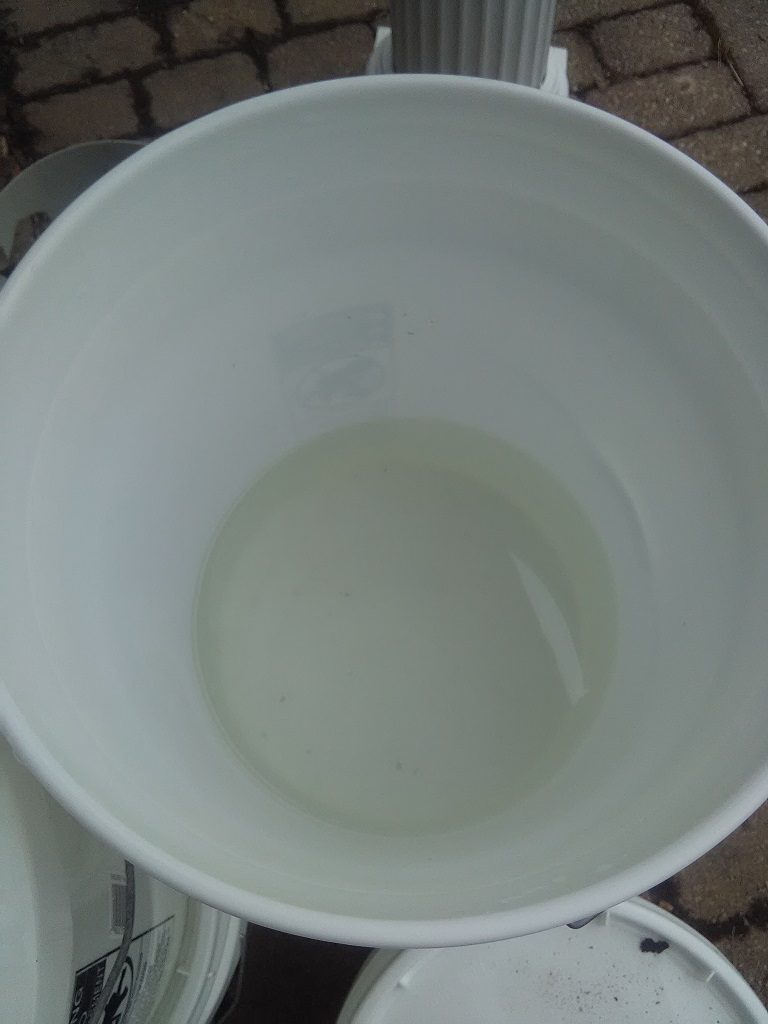

Stages Of Maple Sap

I was surprised to find out people think maple sap is yellow. I never really thought about it, but I happened to see “maple water” for sale at a market. Clear liquid in a clear glass bottle. The ingredients were 100% maple sap … so I knew it was clear before I’d even thought to wonder. I’ve seen sap with a slightly yellow tint. We pull the taps as the tree leaves begin to bud, so it is possible the sap yellows more throughout the year. But maple sap is clear.

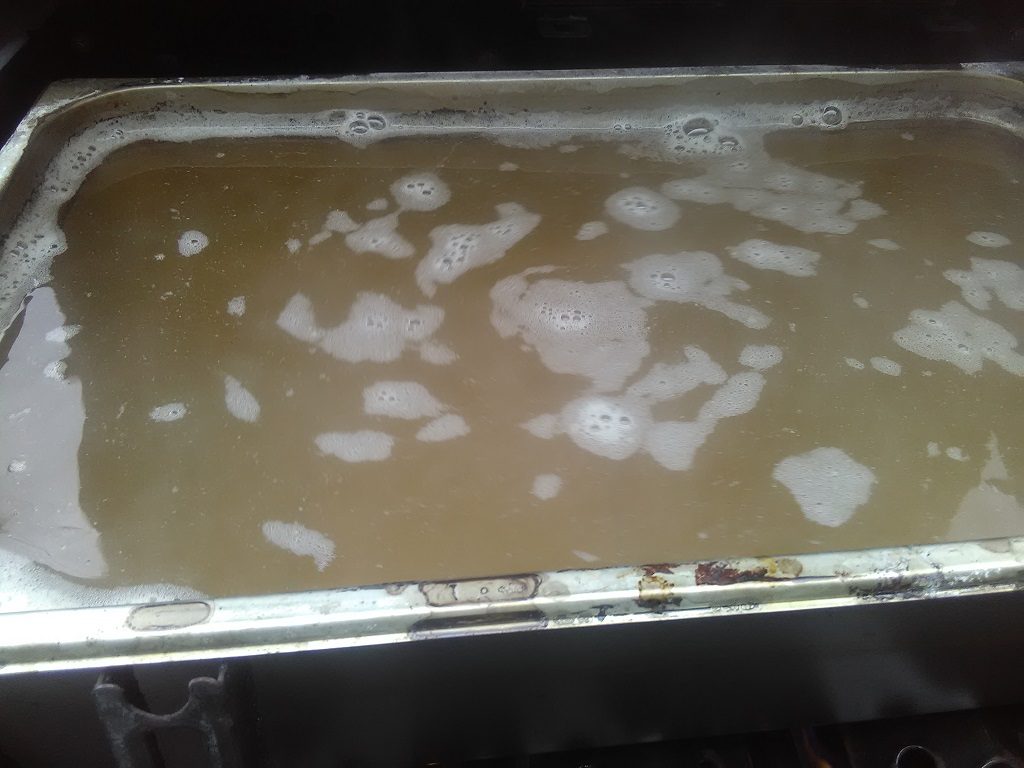

As it is boiled, the sap begins to caramelize. Caramelization is what gives maple syrup a golden brown color – darker syrup is formed from sap harvested later in the year. Lighter syrup is from sap harvested earlier in the year.

As the sap boils down, the color will get darker and the flavor will get sweeter and, well, maple-ier.

Maple Sugaring Season – Boiling Again

We got thirty five gallons of sap from the back woods – combined with the forty two gallons from the front and side property … we have 77 gallons of sap to boil. And more coming!

Maple Sugar Season Update

Strange day. The high here was 68 degrees, and we spent an hour playing in the sand at a beach. Not your normal February activity in these parts.

We got a LOT of sap today – and we only managed to collect the front half of the property. Thirteen trees with fifteen taps yielded thirty eight gallons of sap. Tomorrow, we’ll check the sycamore (hasn’t produced much sap to date, but here’s hoping), two hickories (same story), and ten more maple trees. Lots of boiling ahead, and it looks like it might freeze Sunday night to extend the sap run during the first part of next week.

Maple Sugar Season Update

We are about done boiling off sap from the first run — good timing, too, since it looks like we’re going to have a week or so of really warm weather (should be a good sap flow) followed by a freeze at the end of the month – extending the sugaring season into March.

We pulled the hallow ice cap from most of our buckets, so the sap started slightly concentrated. We’ve condensed about 39 gallons of sap to 2.5 gallons of not-quite-syrup. It will sit in the pan overnight to cool; tomorrow, we’ll filter it and transfer it into a pot. We will finish the syrup indoors.

Maple Season Underway

We’ve finished tapping our maple trees today. We got more than half done this past weekend (fifteen trees, eighteen taps), so managed to hit the awesome tap flow at the beginning of this week.

This year we are going to try tapping one sycamore tree (supposedly a butterscotch flavored syrup) and a hickory tree (no idea what that will taste like). We have twenty four maple trees tapped – a few of our biggest trees have two taps.

Last year was the first year that we tapped maple trees. We hadn’t identified the trees ahead of time, so we didn’t know if we had sugar maples, red maples, not.a.maple trees. We got about forty gallons of sap and used it to brew a dark maple beer.

Early autumn 2016, we took a couple cans of spray-paint, hiked the property looking for trees, and marked the trees with a small spot of paint at the base on the West side of the tree. White paint indicates a sugar maple, red paint indicates a red maple. The hickory trees are shag barks, so fairly easy to identify without leaves. The sycamore is in a unique location along the lake side of our property.

I don’t know if the “tree saver” 5/16″ taps are actually better for the trees, but that’s what we decided to use. As a non-commercial venture, potential reduction in production quantity isn’t detrimental … and I cannot see how they would be worse for the trees than the larger 7/16″ taps.

All of the equipment is stashed in a dump cart. When the ground was frozen, we took our Raven out into the woods. Now that the ground is thawed, we pull the cart by hand. We bought food grade five gallon buckets and lids from Lowes. There are a lot of types of spiles – I wanted stainless steel that we could re-use each year, and I wanted to use tubes instead of buying super expensive hang-on-the-tree buckets. There were still two different types – a straight tap and one that makes a 90 degree angle. It is a lot easier to put the tube on the 90 degree angle ones before inserting into the tree, and they look like they are going to be easier to remove.

We have two different types of tubing: the flexible blue 5/16″ tube meant for maple sap collecting and clear 5/16″ tube that is meant to be a siphon line when brewing beer. At 24$ for 100 foot of tubing, the beer siphon line was a great deal. We’ve got about 100 foot of tubing used for all of our taps.

In addition to these items, we use a battery powered drill with a 5/16″ bit, a small hammer for tapping spiles into trees, a rubber mallet for getting the lids onto the buckets, a little plastic tape measure to check tree size, and a little tool for pulling the lids off of buckets – I could NEVER get lids off plastic buckets, and this tool has turned it into a couple of second task.

With our cart full of tapping gear, we head out into the woods. Grab one bucket and lid, some tube, a spile, and the hammers. You are supposed to drill about three feet up on the tree, but stay at least six inches away from old tap holes. Conventional wisdom is to tap the south side of the tree as that side has sun exposure and will be warmer. I want to log our production per tree from the south side and north side to determine if there is any validity to the practice, but it would be a long-term study of overall production across multiple years to control for weather variations.

Once a hole is drilled, the tap is inserted and the tube pushed onto the tap. The other end of the tube is inserted into the bucket. On level ground, we just leave the bucket sitting next to the tree. In other cases, we use ratcheting straps around the tree and hang the bucket from one of the strap hooks.

We should begin boiling our sap tomorrow – yesterday was an awesome day for sap flow, and we had a lot of 1/2 to 2/3 filled buckets. It’s going to be below freezing for about 36 hours, so figured we could leave the buckets out overnight and begin collecting them tomorrow.

Lessons learned so far: (1) Buy your equipment in the off season. I bought stainless steel taps for under 1$ each, but we needed more taps that I’d purchased. They’re 2.50$ each! (2) Get more storage vessels than you think you need — we have twenty six 5 gallon buckets out in the woods and are scrounging around to find storage containers for collected sap. (3) Collect sap often. Twenty six full five gallon buckets is 130 gallons of sap! If each bucket was emptied when it had two gallons, that’s 52 gallons of sap that gets boiled down to just over a gallon of maple syrup … two or three times, but still it is easier to find a place to store 50 gallons of sap and a couple gallons of maple syrup than it is to find holding containers for 130 gallons of sap.