We have a greenhouse full of turkeys! It was turkey liberation day at the farm — all of the poults that hatched last week are now in a larger brooder in the greenhouse. They’ve got a larger “turkey toaster” (a plate heater) for the evenings, but they are running around, exploring, and happily eating green leafy things.

Tag: greenhouse

Greenhouse Reinforcement

The biggest problem I’ve seen with the cheap metal frame / plastic covering high tunnel greenhouses is that water will pool up on the top, and the weight of the water will collapse the whole thing.

I’ve seen a few different approaches to preventing the plastic from forming a dish and holding gallons of water. We opted for a simpler route that has, thus far, proven effective. We bought three EMT tubes — metal tubes — to create a firmer ridge-line in the greenhouse. I had 1/2″ CPVC tubing from the low tunnel greenhouse. From being held in an arch over several seasons, it was permanently bent. We cut those tubes in half, and placed them above the ridge line tubes. The ends were then pulled under the next set of horizontal bars of the greenhouse frame. This holds them in place firmly. They prevent water from pooling — the last section of the greenhouse still does pool, so I will eventually add something else in that section. It is, however, a small enough weight that the greenhouse frame can support it.

Greenhouse Repair

Last year, we built a 26′ greenhouse in the garden. It took a few days to get everything sorted, and we tried a few different methods to adhere the thing to the ground without any stunning successes. As we disconnected our most recent attempt, our phones blared a weather alert. A severe thunderstorm was headed our way! Looking to the west, it was really close. Rain started to fall and thunder cracked. We ran inside. For the next half hour, we all stood at the front windows watching the greenhouse not budge in this storm. Until …

My lovely greenhouse went somersaulting across the yard and became impaled on a tree. We extracted it and checked it over — some bent metal tubes, a broken tube, and several holes in the cover. It was so late in the year that we decided we didn’t actually need a greenhouse for the year & left it as a project for early spring this year. We did, however, purchase a few sections of 10′ EMT last year in preparation for the repair. Well, it’s early spring!

Scott pounded the end of an EMT and bent it in the vice, then drilled it to recreate the broken bottom pole. We fastened an EMT to a few bent tubes.

He then cut a section of copper tube and cross-drilled it so it could fit across the two sides of a broken tube.

A little more bending and straightening, and we were ready to put the cover on again. This time, there are dozens of concrete blocks holding it down. It’s been up for more than 24 hours … so we’re doing better than last year! Tomorrow, we’ll move the started plants into the greenhouse.

Greenhouse Construction – Part 2

Greenhouse Construction – Part 1

Home Automation and Gardening

Something like 20 years ago, I tried to grow a plumeria flower in my apartment. I had a broad-spectrum light, plenty of heat, and plenty of humidity. But getting the light turned on and off at the right times wasn’t easy (especially if I was at work all day!).

This seems like a really good use for home automation — our home automation system tracks the sunrise and sunset times for our zip code. It’s possible to essentially cron “stuff” off of these times — e.g. get the birds ten minutes before sunset. I could easily track sunrise and sunset in Honolulu then have my light turn on at sunrise (or first light) and off at sunset (or last light). Voila — “sunlight” that runs for the proper duration every day.

(Mostly) Fits In a Volt

Harbor Freight had one of their 20% off coupon sales for Fathers Day. We’ve been wanting to buy the 10×12 greenhouse for a while, and 20% off was the perfect opportunity to do so. There’s a site where someone details all of the tweaks they used to enhance the structure — we’ll be making a lot of these enhancements as we build the thing.

One of these days, we’ll have an electric farm truck running … but, until then, a 10×12 greenhouse in its box #FitsInAVolt … at least sufficiently to transport it a short distance home!

Hop Greenhouse Redux

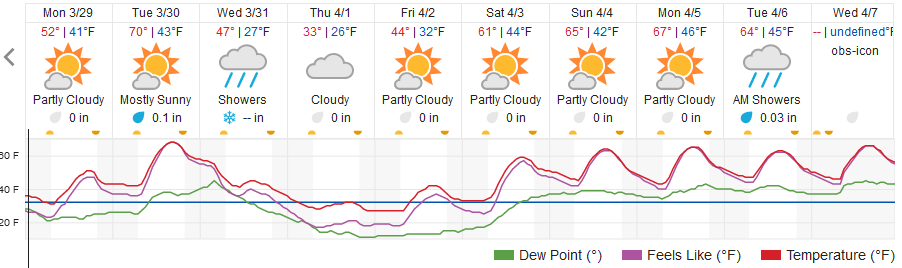

So we’re supposed to get five or six inches of snow tonight, and tomorrow night will get down to 28 degrees or so … which means the hop greenhouse is back! It’s sturdier this time so it’ll handle the snow load. There are two logs on each side, both with a long 2×6 board run across. Shorter 2×4’s were laid across the long boards to provide support for the roof. There are additional boards diagonal from the “roof” to the ground. The whole thing is covered with greenhouse plastic, and 4×4’s (and a few large logs) weigh down the edges.

I’ve also got plastic bags over the blueberries, raspberries, elderberries, baby pawpaws, garlic, and baby black walnuts. There’s a tarp over the part of the deer garden that’s actually sprouted. Hopefully everything fairs well. The hazelnuts aren’t protected — they’ve gotten quite large, but they should have plenty of energy in the root system. The kale isn’t protected either, but it survived the winter already … so that should be fine.

Temporary Hop Greenhouse

We’re in for a drastic temperature drop this week — 70 degrees one day, 27 the next night. We’ve covered our hops before; but, as the plants spread out, they get harder to cover.

This year, we built a quick (temporary) greenhouse over the entire hop bed. Rebar and longer metal poles are pounded into the ground at an angle, and the 1″ PVC that I had for the low tunnel greenhouse is mounted to the poles. A large sheet of greenhouse plastic covers the entire bed, and a lot of bricks are (hopefully) holding it all in place. This should keep our new hops from freezing.